Engines are much more complicated today than they were years ago. They are much less complicated than many people think, though. At its core, an engine in nothing more than an air pump.

Seriously, that’s all!

Besides all the added technology that makes our cars produce the power they do, and be as efficient as they are, the internal combustion engine is still doing the same thing it’s done for over 100 years.

We’re going to look at how it works. More specifically, we are going to break down a typical four stroke internal combustion engine to show you, at the most basic level possible, how it works.

For now, we aren’t going to touch diesel engines, two-stroke engines, and battery-powered engines. Those are for another time and place.

The Four Stroke Engine:

The four stroke engine is the engine that most people think of when they think about a car. The four strokes are intake, compression, combustion, and exhaust. There are a few parts that put all of this together, so let’s take a look at them.

How it all Works:

We are going to look at all the basic parts that make the four strokes of a normal vehicle engine run. If we included every single component of an engine, we’d be here for a long time. Though there are many more components that make up most normal vehicle engines, we’re sticking to the basics.

Air Filter:

Photo: Courtesy of Auto Anything

All the air that is sucked into the engine comes through the air filter. It’s the very first part of the very first step in the engine making power, and it’s a good thing. Nobody wants dirt, dust, or other foreign material getting into their engine and causing major damage. The air filter makes sure nothing beside air gets through.

Throttle Body:

The throttle body contains a throttle valve that controls the amount of air allowed into the engine. The more air that gets into the engine, the more power can be produced. As the accelerator is pressed the throttle valve is opened wider.

The throttle body is located between the air filter and the intake manifold in most modern vehicles. Older vehicles that use carbureted engines function slightly differently.

Intake Manifold:

Photo: Courtesy of Auto Ricambi

The intake manifold distributes the air coming into the engine evenly throughout each cylinder within the engine. In a four cylinder engine, the manifold will distribute the air four ways. In a six cylinder engine, the manifold will distribute the air six different ways, and on it goes depending on how many cylinders an engine has.

Cars with carbureted engines function a little differently. The intake manifold distributes the air and fuel mixture appropriately to each cylinder rather than just air to be ignited within the cylinder itself.

Cylinder Head:

Photo: Courtesy of Sandvik Coromant

The cylinder head sits on top of the engine block and serves several purposes. It seals each cylinder at the top of the engine to form each cylinder, it contains the intake and exhaust valves, and it forms the barrier to allow intake air to be compressed and combusted to make power.

Without the cylinder head, the engine would be open at the top, and there wouldn’t be any way to power the vehicle as combustion would be impossible.

Camshaft:

Photo: Courtesy of Delorean Industries

The camshaft is a spinning rod with lobes used to open and close the intake and exhaust valves within the engine. Most vehicles have either a single or a dual camshaft.

Camshafts can operate directly or indirectly. The lobes on a camshaft can function directly by pushing a valve open, or they can operate through a series of pushrods. Pushrods are pushed up by a rotating lobe of a camshaft, which then operate a seesaw-like device called a rocker arm. The rocker arm is pushed up on one side by a pushrod and down on the other side, opening a valve to allow air in or exhaust out.

In order to time the opening and closing of the intake and exhaust valves correctly, a timing chain or timing belt is used to connect the camshaft with the crankshaft. This ensures that air gets into the engine when it should and exhaust is pushed out when it should. If the timing is incorrect, exhaust gas could be pushed out during the intake cycle.

If the timing is off, the very least that could happen is that the vehicle won’t run correctly. The worst that could happen is a catastrophic engine failure.

Intake Valve:

Photo: Courtesy of Speedway Motors

The intake valve is what actually allows air to enter a cylinder. A valve looks like a miniature trumpet and is pressed downward to open and allow air into the engine’s cylinder. The valve will close after enough air is emptied into a cylinder to seal it and allow the air to be compressed against the cylinder head.

Fuel Injection system:

An engine needs more than just air to make power. Some kind of fuel needs to be mixed with air to provide an appropriate mixture which will enable an engine to run smoothly, efficiently, and appropriately. Gasoline or diesel are the most common types of fuel used in combustion engines.

Every car needs fuel system to deliver the fuel that provides the combustion an engine needs to create power. Most modern cars use a direct injection or port injection system. Many older cars utilize a carburetor to provide fuel to the engine.

Direct Injection:

Direct injection has become popular over the past decade as the potential for better fuel efficiency is much greater in this type of fuel system than in carbureted systems of the past.

A direct injection fuel system is fairly self-explanatory. Gasoline is injected directly into each cylinder from the fuel injector located in the cylinder head. This allows for incoming air to mix with the fuel in the cylinder.

Port Injection:

Port injection is another popular method of fuel delivery. Many modern cars have both direct and port injected fuel systems. This allows the benefits of both systems to be utilized.

Port injection systems deliver the fuel within the intake manifold or just outside the cylinder rather than within the cylinder itself. Fuel is mixed with the air coming into the engine before it enters the cylinder to be compressed and ignited.

Carburetor:

Carburetors used to be the most common fuel delivery systems in a vehicle, but they can’t match the efficiency of modern directly injected engines.

Carburetors allow air to be brought in through an open tube above the engine and mixed with fuel. There is a venturi, or narrowed section of tubing, that changes the pressure of the airflow. A valve, operated by the accelerator, controls the amount of air coming through the tube.

The more airflow that’s allowed by opening the valve, the more fuel is pulled through the venturi because of the pressure change and consequent acceleration of airflow to the engine. Because fuel isn’t injected, carburetors tend to be less efficient than other fuel systems.

Sparkplug:

Photo: Courtesy of Advance Auto Parts

Regardless of the fuel system, there has to be an ignition source that creates the actual combustion of the air and fuel mixture. The sparkplug is what causes the spark which creates combustion.

Diesel engines don’t require spark plugs because their ignition relies on the high temperature of the air and fuel mixture as it becomes compressed. Once the appropriate temperature is reached, the fuel and air will ignite on their own and push the piston downward.

Engine Block:

The engine block is the largest and heaviest part of an actual engine. It’s basically the chunk of metal used to carve out however many cylinders an engine will have. An engine block is usually made of cast iron alloy or aluminum alloy. Variations with other materials can also be used in the manufacturing an engine block.

Engine blocks often contain cooling channels and can sometimes include other components like the cylinder head. The definition of an engine block and what all is included will vary slightly depending on who you ask.

Cylinder:

A cylinder is bored out of an engine block and is the entire housing that contains everything needed to compress and ignite the air needed to create the vehicle’s power.

Piston:

The piston is the part of the engine that actually moves up and down to compress the air within each cylinder. Unlike the cylinder head which seals the top of the cylinder and bolts onto the block making it stationary, the piston is a moving part that seals the bottom of the cylinder.

As the piston moves downward, it sucks in air or the air and fuel mixture to be compressed by its next upward movement. After combustion, the piston pushes the exhaust, caused by the explosion, out of the cylinder through the exhaust valve.

Connecting Rod:

The connecting rod connects the actual piston to the camshaft at the bottom of the engine.

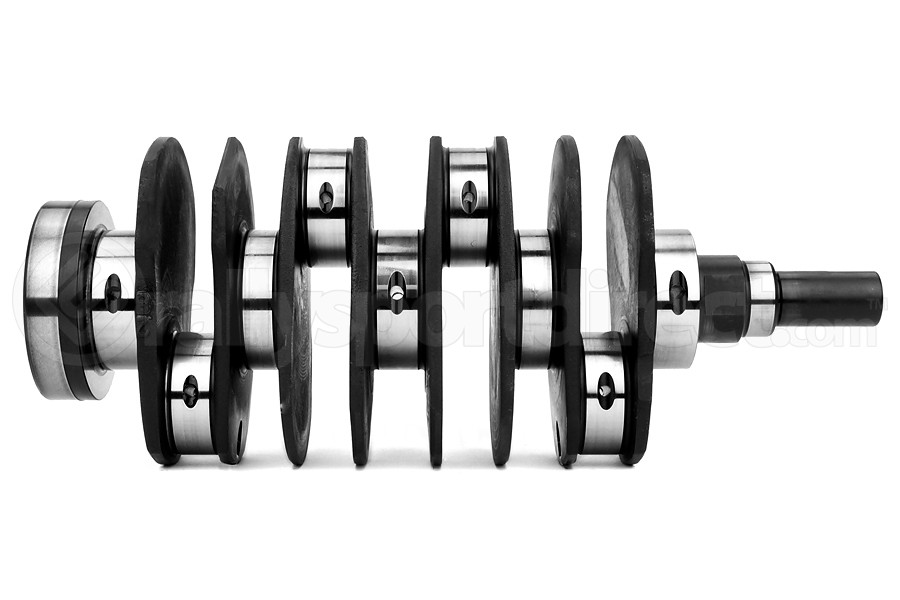

Crankshaft:

Photo: Courtesy of Rallisport Direct

The crankshaft is located at the bottom of the engine block. As the air and fuel mix to create combustion within the cylinder, the upward and downward movement created by the piston causes the crankshaft to spin. This spinning is ultimately what enables the vehicle’s wheels to spin when the power is created.

Exhaust Valve:

The exhaust valve is the sibling of the intake valve. It will open after the air and fuel mixture has been ignited and after the piston has been pushed back down as a result of the ignition. As the piston rises again, it pushes the leftover exhaust gasses out the open exhaust valve and through the exhaust manifold.

Exhaust Manifold:

The exhaust manifold does the exact opposite of the intake manifold. Whereas the intake manifold distributes the incoming air evenly to each cylinder, the exhaust manifold collects the exhausts gases from each cylinder into one pipe to be expelled.

Exhaust System:

Photo: Courtesy of Research Gate

Exhaust systems usually consist of everything after the exhaust manifold. Most of this is piping to take exhaust gases away from the car, the catalytic converter, and any kind of muffler or mufflers used to quiet the sound of a vehicle.

Catalytic Converter:

Besides piping, the catalytic converter is the first part of the exhaust system. It cleans the harmful exhaust gases of toxic chemicals that accompany the spent exhaust. Because of this, there are regulations against having a car without a catalytic converter.

Muffler:

A muffler is a chamber along the exhaust piping of a car that allows the sound of the engine to be dispersed and muffled. Most mufflers are at the rear of a vehicle, but there are some cars that have multiple mufflers placed at various points underneath the car.

After everything is said and done, the exhaust leaves the vehicle through the tailpipes. The cycle is complete.

Of course that isn’t every single component of a four stroke internal combustion engine. There are hundreds of other components that are used on some cars that aren’t on others. Wiring for all the electric components are used to regulate sensors and control each part. Coolant, oil, and power steering fluid are all housed in compartments under the hood, and all are vital to the engine’s proper function.

In other words, all of this is just the tip of the iceberg. Hopefully you have learned something. If you still haven’t gotten everything down, that’s OK. Check back with us next week for part two of “how an engine works.”